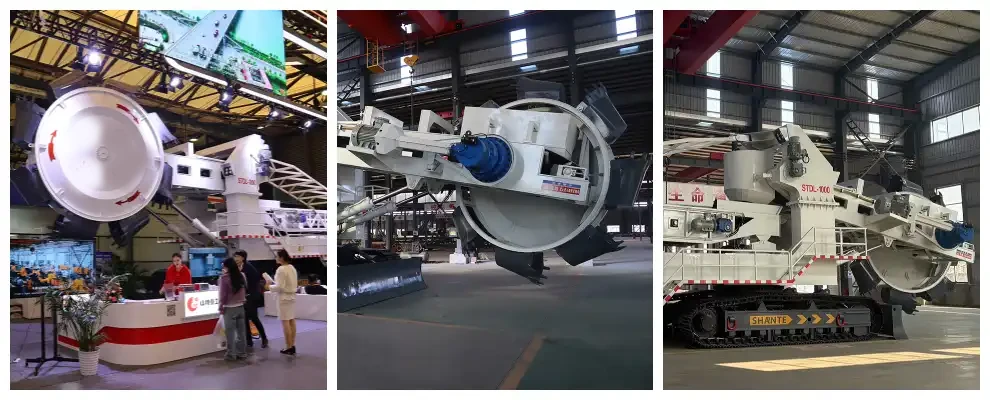

Product Introduction

High efficiency: The bucket wheel machine has a powerful loading capacity, capable of handling a large amount of materials at one time and transporting them efficiently to the destination. Its fast loading and unloading speed enables it to complete a large number of handling tasks in a short time, significantly improving production efficiency.

Wide application range: Bucket wheel machines are not only suitable for large logistics hubs such as coal terminals and ports, but also for material handling and drying operations in industries like construction, metallurgy, and chemical engineering. They have strong adaptability and cover a wide range of tasks

Strong continuous operation capacity: The bucket wheel machine adopts a non-stop continuous operation mode, and its continuous productivity is superior to that of traditional loading and unloading machinery.

Efficient and reliable: The bucket wheel machine is equipped with advanced operation and transportation systems, capable of quickly performing large-scale material handling and stacking tasks. The integrated control and monitoring system can track the machine status in real time, enhancing the reliability and safety of operation.

Easy maintenance: The bucket wheel machine adopts a modular design, which simplifies maintenance and component replacement, and reduces the overall operation and maintenance costs.

Humanized operation: The bucket wheel machine is easy to operate and understand. Just receive basic training, be familiar with the control interface, button functions, as well as the working principle and process of the equipment, and you can operate the machine efficiently. Operators only need very little technical knowledge and follow safety regulations to ensure the stable and efficient operation of the machine.

project | unit | STDL-2000 |

| Overall dimensions (length × width × height) | mm | 30000×5900×8300 |

| Bucket wheel diameter | mm | 5800 |

| Bucket wheel arm length | mm | 11280 |

| Bucket wheel capacity | Cubic meter/piece | 0.42 |

| Number of buckets | piece | 14 |

| Rated output | cubic meters/hour | 2000 |

| Material density | Tons/cubic meter | (0.8-1.8)×10³ |

| Discharge arm length | mm | 9000+5000 |

| Discharge conveyor length | mm | 36,000 |

| Maximum stacking height of unloading conveyor | mm | 8000 |

| strength | kilowatt | 509 |

| Conveyor specifications | mm | 1400 |

| Conveyor belt speed | Multiple sclerosis | 2.8 |

| Equipment weight | T | 168 |

| Bucket wheel speed (rpm) | Speed/second | 6.8 |

| Driving speed. | m/min | 20 |

| Luffing angle | ° | ±18 |

| Rotation angle | ° | 135 |