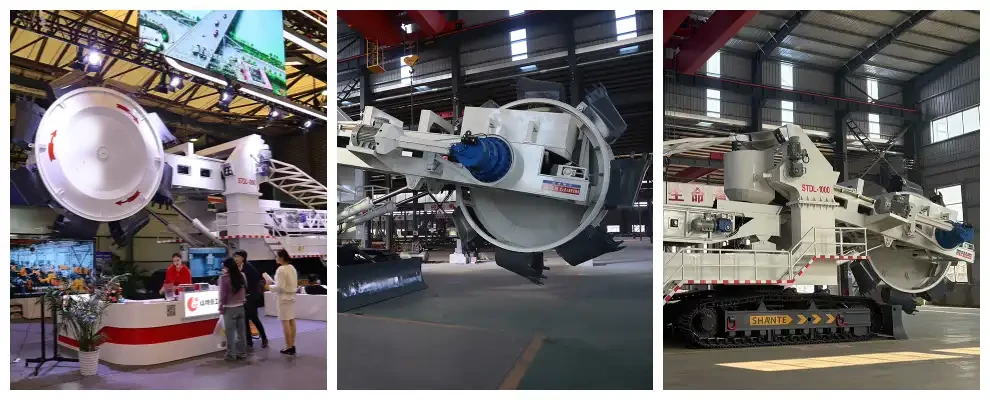

Product Introduction

Port economic bucket wheel stacker-reclaimer

When the bucket wheel excavator is stationary, material extraction is carried out. The synchronous rotation of its front tool assembly and the hinge device of the boom is utilized to shear and collect the substrate. During the rotation process, the bucket rises, and the captured materials are unloaded onto the feeding conveyor under the effect of gravity. Subsequently, they are conveyed through the bucket to the unloading and conveying pipeline for unloading. After stratified excavation, the equipment moves forward or adjusts the height of the boom to excavate the subsequent strata. The excavation depth corresponds to the linear displacement or the extension range of the boom, while the operation width is controlled by the rotational speed. The mobile function provides support, prioritizing continuous cutting through material transfer mediated by rotating components and conveyors.

Structural composition

This equipment integrates six main subsystems: the mobile base, the rotary drive device, the excavation device, the material conveying network, the electric propulsion frame and the hydraulic management system. The key design aspects include:

Mobile base

Modern configurations mainly adopt crawler walking systems, while some models use articulated walking mechanisms. Medium-sized equipment usually adopts a double-track design, while heavy-duty equipment uses a multi-track layout to optimize the dispersion of ground pressure.

Omnidirectional rotary drive system

This component combines a rotating superstructure and a directional propulsion component, and contains a power generation system, transmission infrastructure, control interfaces and an operator's working area. The precisely designed slewing bearings ensure that the rotational capacity around the vertical axis is unrestricted.

Excavation unit

It includes a radial bucket array, articulated boom, height control mechanism and transmission system. The cutting assembly (circular excavation container array) is located at the end of the boom. The boom rotates through a portal hinge and is angle-calibrated by a tensioning system or hydraulic actuator to maintain the optimal cutting geometry. The configuration includes two types: rigid boom and telescopic boom, and is equipped with laterally installed drive modules (motors with safety torque regulation and gear transmission) to achieve efficient power transmission.

Material routing network

The operation is carried out through the sequentially arranged feeding and discharging conveyors as well as the intermediate buffer hoppers. The bridge-type configuration unit integrates the auxiliary transfer conveyor into the bridge superstructure to enhance the adaptability of the material flow.

Electric propulsion framework

The precise optimization of motor speed and torque is achieved through grid synchronous frequency conversion regulation.

Hydraulic management system

The lifting of the boom and the alignment of the conveyor belt are mainly controlled by fluid power actuators to ensure the dynamic operation accuracy during the excavation cycle.

High cost-performance bucket wheel stacker-reclaimer for ports |

|||

Project |

Unit |

Technical specifications |

|

Overall dimensions - length × width × height |

millimeter |

21090 * 4000 * 5888 |

|

Track size |

millimeter |

5700 x 600 |

|

Track plate width |

millimeter |

600 |

|

Track-driven hydraulic motor |

/ |

Hydraulic motor + reducer |

|

Teack drives the hydraulic pump |

/ |

Danfoss |

|

Hydraulic pump drive motor |

Kilowatt |

45 |

|

The bucket wheel arm is long |

millimeter |

8280 |

|

Length of the unloading arm |

millimeter |

8000 + 3000 |

|

Rated output |

Cubic meters per hour |

900 |

|

Bucket wheel diameter |

millimeter |

3600 |

|

Bucket wheel rotational speed |

Revolutions/minutes |

0-8 |

|

The volume of each bucket wheel |

Cubic meters |

0.3 |

|

The number of buckets |

slice |

8 |

|

Bucket wheel pitch Angle |

° |

25 ~ 5 |

|

Material density |

Tons per cubic meter |

0.8 ~ 1.8 |

|

Turning radius of the bucket wheel |

millimeter |

10036 |

|

Width of the material taking conveyor belt |

millimeter |

1200 |

|

The rotation Angle of the bucket wheel |

° |

+ 180 |

|

Width of the unloading conveyor belt |

millimeter |

1000 |

|

Length of the unloading conveyor belt |

millimeter |

29524 |

|

The rotation Angle of the unloading conveyor belt |

° |

+ 65 |

|

Pitch Angle of the unloading conveyor belt |

° |

0-16 |

|

The maximum stacking height of the unloading conveyor belt |

millimeter |

6500 |

|

Drive form of telescopic mechanism |

/ |

Hydraulic cylinder |

|

Overload protection method for bucket wheels |

/ |

Automatic |

|

Matching motor power |

Track walking drive | Kilowatt | 45 |

| Bucket wheel swing drive | Kilowatt | 75 | |

| Bucket wheel conveyor belt drive | Kilowatt | 15 * 2 | |

| Discharge conveyor belt drive | Kilowatt | 15 * 2 | |

| Engine power | Track walking drive | Kilowatt | 105 |