Product Details

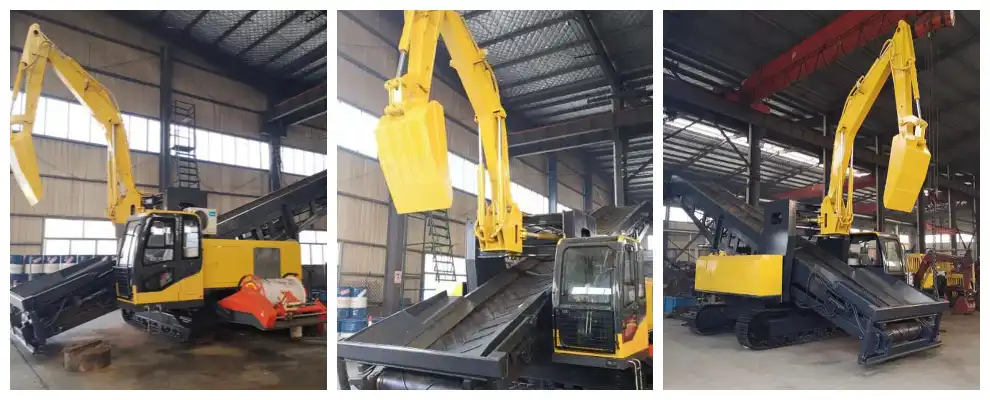

Innovation-driven mechanism

This conveyor belt-based unloader is equipped with a three-phase motor, ensuring flexible performance, low maintenance costs, zero-emission operation, and reduced downtime. Compared with the traditional engine drive scheme, the electric propulsion system can reduce operating costs by 66%.

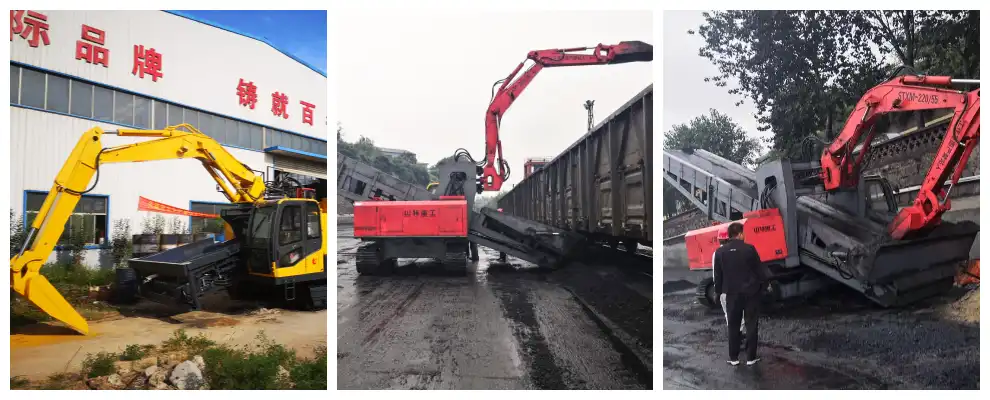

Sustainable material conveying

Aimed at eliminating coal leakage and air particulate matter pollution. The rear-loading design can directly transport coal to the transportation unit, which complies with energy conservation and environmental protection regulations.

Spatially optimized entrance structure

The sealed feeding mechanism can prevent coal from depositing on the track, maintain the hygiene of the work site and minimize the cleaning work after the mission.

Comprehensive extraction capabilities

Ensure that the coal is completely discharged from the cargo hold to reduce the workload of manual residue removal.

Climate control technology

Adopting an intelligent HVAC system, it provides multi-dimensional airflow, continuous air renewal and ozone-safe refrigerants to enhance the ergonomics of the operator.

"Outstanding Operations

Synchronous dual-pump hydraulics and multi-functional automation have enhanced the material transfer rate and process efficiency.

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||