Product Introduction

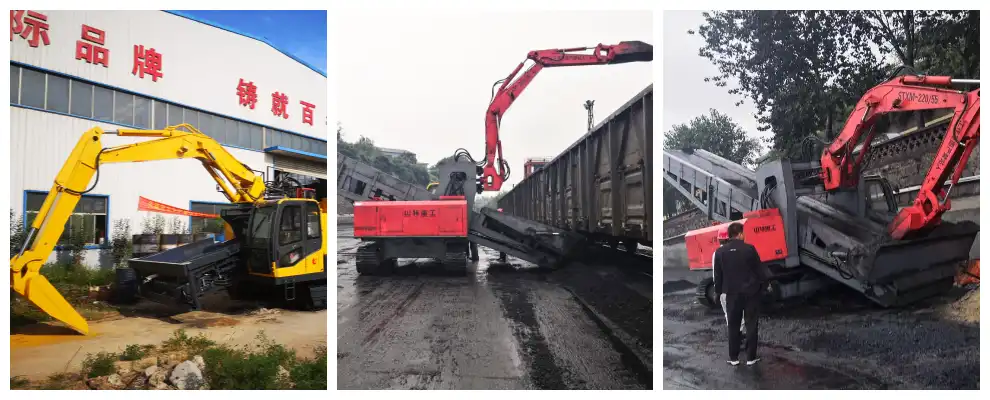

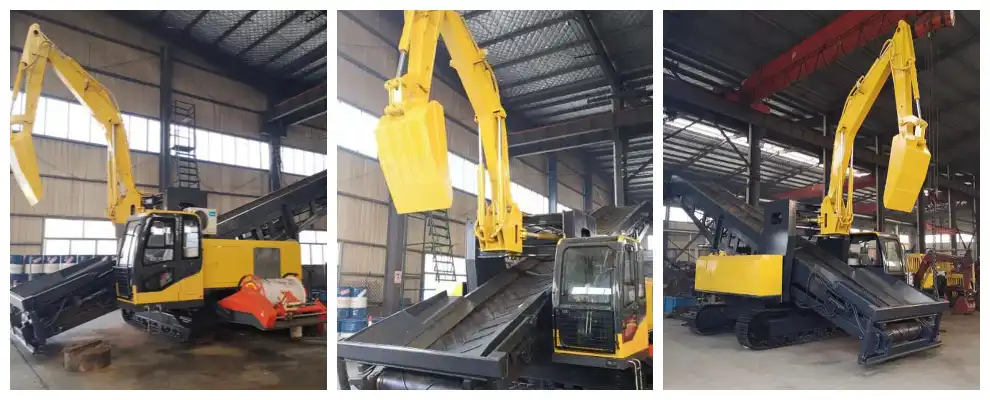

Easy-to-operate track unloader

Environmentally friendly power system

These devices are driven by three-phase motors, enhancing operational flexibility. Electric propulsion systems can ensure the lowest maintenance requirements, zero-emission performance and higher reliability. The energy cost of an electric motor is approximately one third of that of a traditional fuel engine.

Ground-to-vehicle transfer system

Coal is directly conveyed from the unloader to the transport truck via a rear-mounted belt, avoiding ground deposition and secondary dust emissions. This method supports sustainable development and reduces environmental pollution.

Leak-proof feed inlet design

The closed feeding port saves space and effectively prevents coal from scattering onto the tracks, ensuring smooth train operation. This innovative design can keep the workplace clean and tidy and reduce the post-operation cleaning work of staff.

Vehicle unloading capacity

The expanded operating range can ensure that the coal on the rail vehicle is completely removed, greatly reducing the reliance on manual cleaning and alleviating the labor pressure.

Intelligent environmental control

This system adopts omnidirectional airflow technology to continuously maintain the exchange of fresh air and uses non-toxic and fluorine-free coolants. Its powerful automated thermal management function can optimize heating and cooling efficiency.

Simplified productivity improvement

By integrating the hydraulic synergy of dual pumps and a coordinated multi-process workflow, this equipment achieves a significantly accelerated unloading speed and outstanding output compared to traditional alternatives.

A simple-to-operate track unloader |

|||

Project |

Unit |

STX-220 |

|

Overall dimensions - length × width × height |

millimeter |

10277 * 5530 * 3550 |

|

Working weight |

T |

Material 20 |

|

Efficiency |

Tons of lump coal per minute |

3-10 |

|

Bucket size |

millimeter |

1250 * 950 * 450 |

|

Engine |

Main motor power |

Kilowatt |

55 |

Rotational speed |

Revolutions/minutes |

1450 |

|

Belt motor power |

Kilowatt |

22 * 2 |

|

Hydraulic system |

Main pump | / | Imported variable piston pump |

| Rated flow | Liters per minute | 220 | |

| Work pressure | Megapascal | thirty | |

| Main valve | / | Rexroth | |

| Capacity of the hydraulic oil tank | The left | 220 | |

| Walking motor | / | Doosan, South Korea | |

Performance parameters |

Belt speed | Multiple sclerosis | 2 |

| Belt width | meter | 1.2 | |

| Belt Angle | ° | 22 | |

| Fully enclosed cab | / | Aviation seats and hydraulic operation | |

| Automatic cable arrangement device | meter | 100 | |

| Electrical system | Santak Heavy Industry | ||

| Oil cylinder | Imported seals (Constant force) | ||

| Hose | Italian/Qingdao Oak VI | ||