Product Introduction

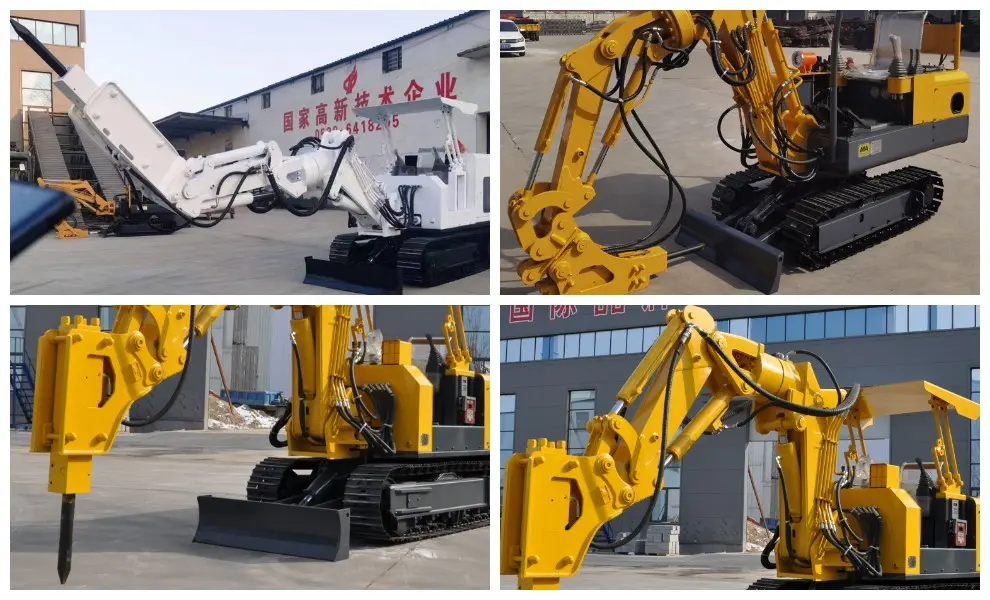

Explosion-proof tunnel repair machine.

Automated tunnel maintenance solution: A compact and quiet system that redefines underground repair through intelligent mechanization and operational flexibility.

The main difference lies in:

Multi-functional hinge unit.

Provide precise excavation and material coordination.

Combining six operation modes: excavation, rotation, rock removal, load handling, lifting and structure modification.

End-to-end maintenance mastery.

End-to-end maintenance mastery.

Structural beam integration/removal technology.

Manage the construction of drainage systems, surface improvement, waste clearance and maintenance of transmission systems.

Promote auxiliary tasks: equipment mobilization and material recombination.

Environmental protection hydraulic system

Integrated low-power power center with fluid synchronization function.

Adaptive pressure management enables refined operation control.

A rapid maintenance design with component accessibility.

People-oriented operation

The operator-centered cab is equipped with ergonomic control devices and fatigue-reducing seats.

Simplified control architecture enhances proficiency.

A powerful hydraulic network ensures consistent performance.

Dynamic function adaptation

Seamless tool conversion to address various maintenance challenges.

Expandable hydraulic interfaces suitable for special applications.

The rear mechanism for stabilizing uneven surfaces.

Professional knowledge of material decomposition

Efficiently remove attachments with optimized energy transmission.

Hydraulic energy recovery ensures sustainable operation.

Easy maintenance protocol.

Intelligent security architecture

Atmospheric safety guarantee: Automatically shut down in case of environmental threats.

Fluid health management: Thermal protection and reservoir safety.

Collision prevention: Workers' spatial awareness of safety.

Remote command system: Wireless control with operation analysis.

This solution has pioneered the automation of underground maintenance, providing adaptive tools for excavation, structural reinforcement and material processing in space-constrained environments, and setting a new benchmark for restoration efficiency.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||